production system

The production, in respect of the quality requirements, is carefully studied to optimize the economical aspect of the process and, as a consequence, of the product.

SELVA PIERMARIO SRL has an internal technical office for the design and planning of equipment suitable for the production and the optimization of the production process.

The technical staff are at the client’s disposal in order to guarantee excellent solutions for the success of the product.

Before starting the production of an article, the company produces a prototype to submit for the client’s approval.

design

raw material

The suppliers of raw material are selected and reliable and they all supply the certifications of the quality of the material.

La SELVA PIERMARIO SRL uses:

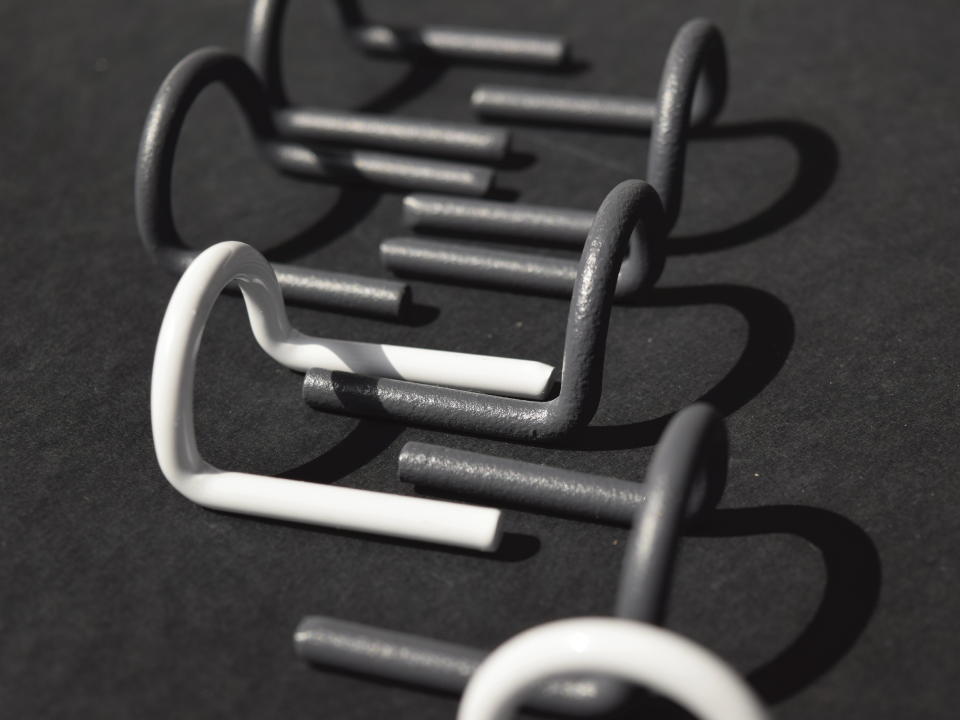

- low tenor of carbon Fe37 and stainless steel wires aisi 300 and aisi 400 (∅ min 1,20 mm – ∅ max 10,00 mm)

- copper – brass – steel aisi 430 – iron F720/K720

- round tube in stainless steel aisi304 (∅ from 5 mm x 0,5 mm to 12 mm x 1 mm)

- round tube Fe36 (∅ from 20 mm x 1,5 mm to 40 mm x 1,5 mm)

- rectangular tube

working procedure

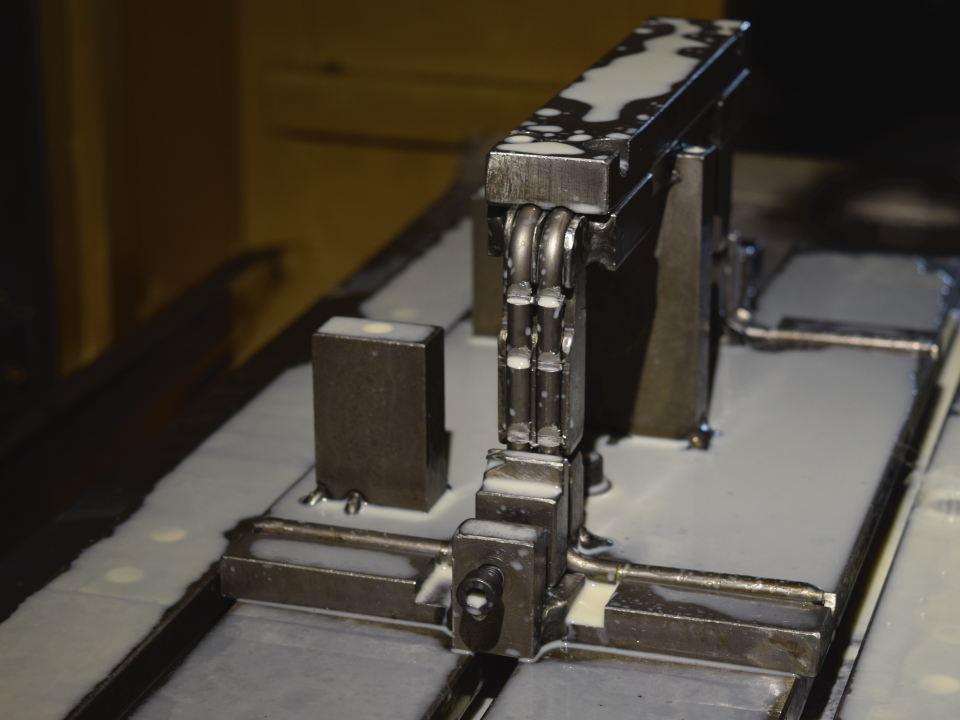

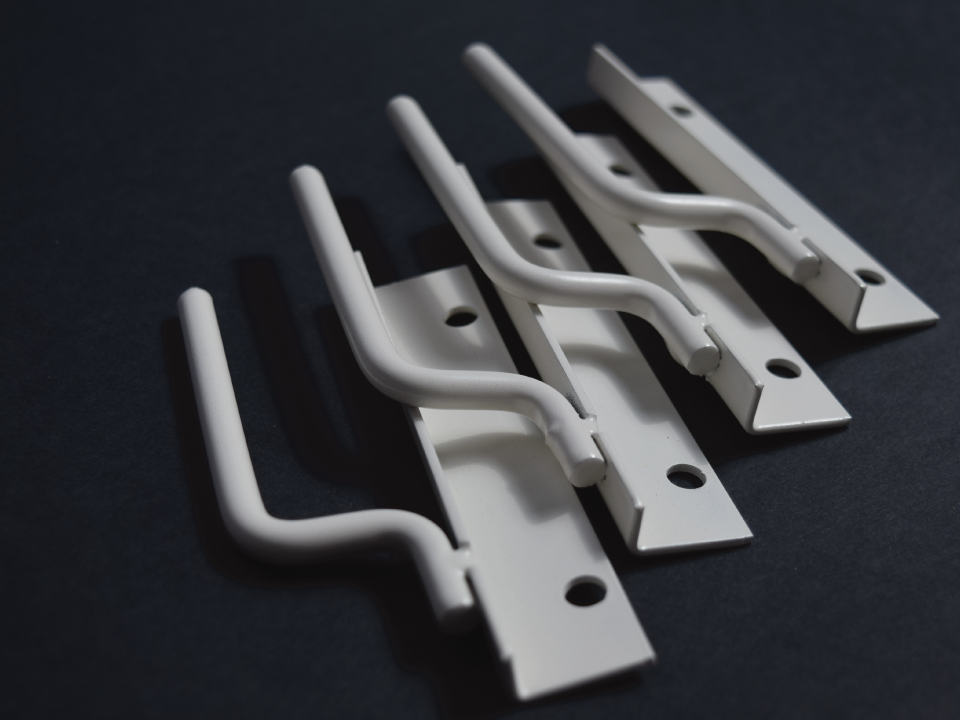

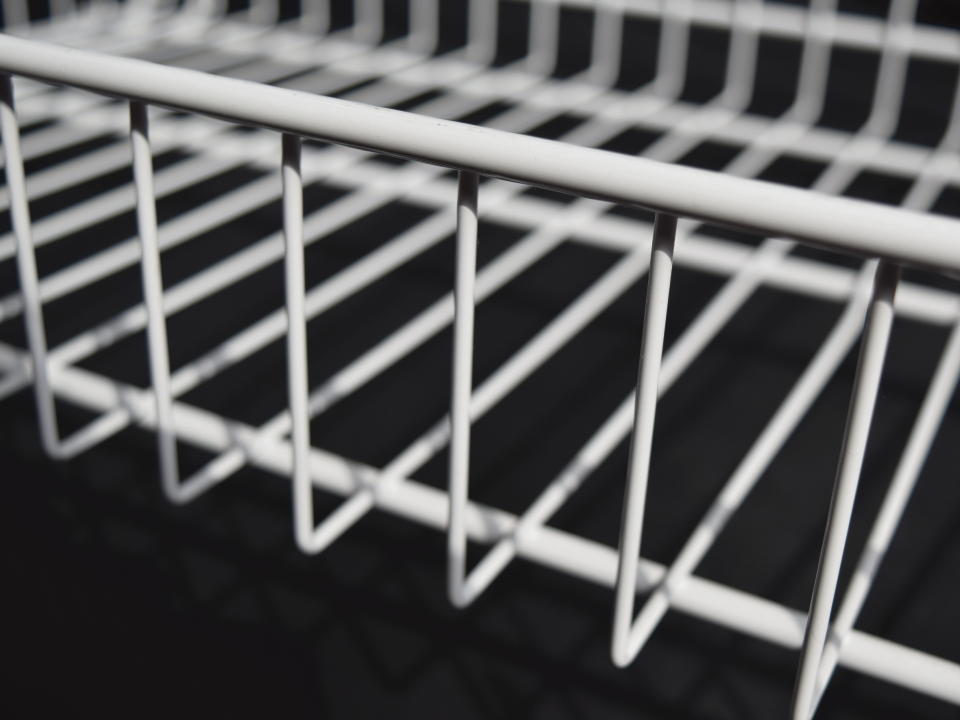

SELVA PIERMARIO SRL carries out folding operations using CNC machinery for three-dimensional folding, multi slide, hydraulic and mechanical press machines, machines for the automatic production of rings and grid frames, machines for folding metal sheets, tubular or flat.

We carry out welding and projection operations using resistance welding machines, MIG, MAG and TIG.

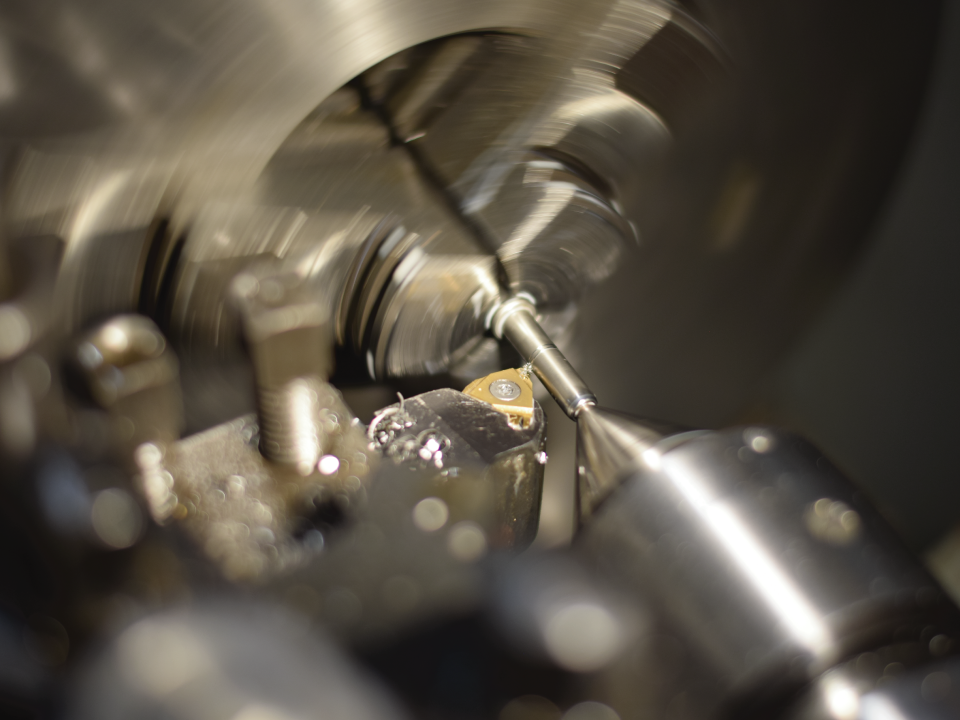

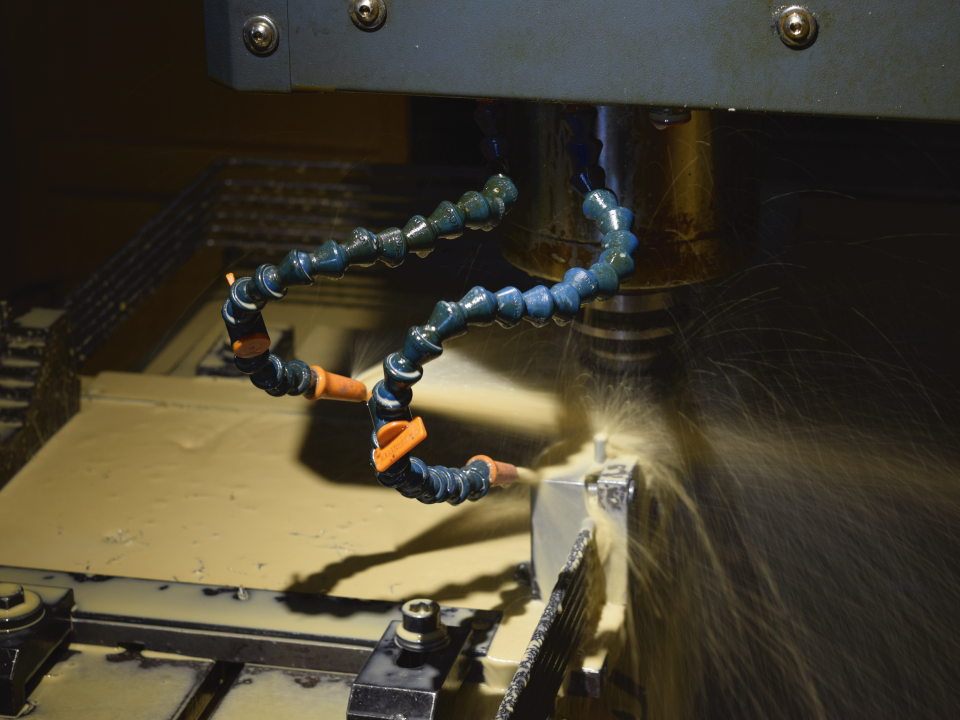

We also do milling, drilling, boring and threading through CNC working centers and CNC lathes.

We carry out pressing using hydraulic and mechanical presses.

finishing treatments

SELVA PIERMARIO SRL has no internal plants for the finishing treatments of the products. These treatments are performed by external suppliers, who have been chosen over the years and who strictly collaborate with the company, operating with the highest standards to achieve the best results. We can usually provide the following treatments: nickel and nickel-chromium plating, metal polishing, electrical polishing of stainless steel, epoxy coating, rilsan coating, zinc-plating and vibratory finishing.

Other special finishing processes can be supplied on request.

packing and shipping

SELVA PIERMARIO SRL carries out quality control tests at various stages during all the production process. Before packing, we carry out an accurate analysis and for some articles a control is made on each single piece. The products ready for shipping are often packed in strong carton boxes and/or on pallets.

Every package carries labels identifying the article, the order reference and quantity. The shipment can take place directly with our means of transport or by chosen forwarders.